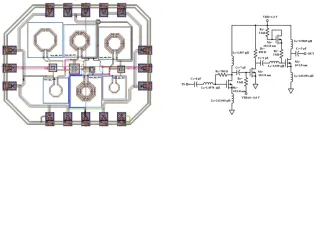

A hotwire sensor is used as the sensor for hotwire anemometry to measure usually turbulence level of a flow. To measure turbulence, a high frequency device such as the hotwire anemometry is needed. The most popular type is a constant temperature anemometry (CTA). The sensor is maintained at approximately 300C, flow causes lost of heat and additional currents supplied to maintain constant temperature is inferred as the behaviors of the flow. The sensors, usually in the range of 2.5 - 5 micron diameter platinum core are easily broken. A hotwire fabricator called Hotwire Fabx is necessary to fabricate a new hotwire sensor easily. Wollaston wire with either 2.5 to 5 micron is aligned on the hotwire tip. The tip cleaned with sand paper is applied with flux with some hidrocloric content. Soldering materials is applied just to ensure the wollaston wire is attached to tip. Etching process in 5% nitric acid is required to get the correct sensor length. A microscope and a traverse is needed.

Comment