Ultrasonic and Vacuum System Assisted Fuse Deposition Modeling to Improve Parts Strength and Surface Finish

Potential Commercialised

violet

Reg. ID : 17357

Comments

Description

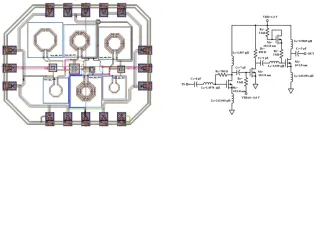

Fuse deposition modelling is one of the additive manufacturing technologies. Fuse deposition modeling is capable to produce 3D printed parts or products with complex geometries. However, it has insufficient strength and poor surface finish which forbids it to be used as end product in various industries. Ultrasonic and vacuum system are both different technologies for different purposes. Interestingly this project has apply these technology to integrated and performed well with fused deposition modeling to address the issue of insufficient strength and poor surface finish of 3D printed parts. Ultrasonic work by producing a mechanical vibration which excites the molten thermoplastic molecules and will produce a rise in temperature. Vacuum on the other hand reduces heat loss by restricting convection of air. This project has proved that the vacuum system was able to improve layer bonding, reduce stress and part distortions thus improve the strength of the parts produced. Conversely, ultrasonic system has been tested to reduce the stair case effect thus improve the surface finish of the parts. Improvement on the surface finish was 14% while vacuum system improves part strength by 22%.

Contact Person/Inventor

| Name | Contact Phone | |

|---|---|---|

| Dr. Shajahan Bin Maidin | shajahan@utem.edu.my |

Intellectual Property

| № | Type of IP | Registration ID |

|---|---|---|

| 1 | Copyright | LY2017000652 |

Award

| Award Title | Award Achievement | Award Year Received |

|---|---|---|

| 0 | 0 | 0 |

Comment