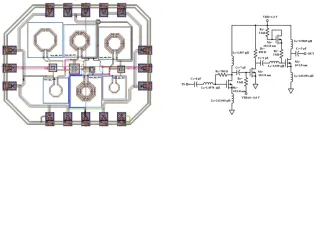

The present invention provides an electrical discharge machining (EDM) assembly that comprises of a common machine frame adapted to house an X-Y positioning apparatus and an electrode assembly, said machine frame comprising of a horizontal support member and a vertical support member, a work-piece holding tank filled with dielectric fluid resting on said X-Y positioning apparatus adapted to secure a workpiece to be machined on, and an EDM electrode assembly comprising of an electrically actuated valve feed mechanism. The X-Y positioning apparatus serving to enable positioning of a work-piece holding tank adapted to secure said work-piece, with the work piece being immersed in dielectric fluid. The work-piece holding tank further being adapted to be in fluid communication with a dielectric filtration system that includes a pump to facilitate circulation of dielectric to and from the work-piece holding tank to a dielectric reservoir and thus serving to provision for the continuous flushing of dielectric fluid contained within the work-piece holding tank.

Comment