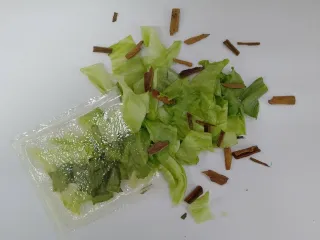

The major sources of land pollution include plastics, metal and glass containers, food wrapping, worn-out machinery, old furniture, garbage, etc. As the mango peels decompose to produce methane gas and contribute methane gas leads to global warming. Hence, the utilization of solid wastes of mango peels into a useful and beneficial product is vital. Mango peels are food wastes that are highly challenging as waste. The peels have polyphenols, carotenoids, and vitamins with excellent antioxidative and functional properties and hence finds potential use for the production of bio-plastic. It also contains pectin, an essential source in providing bio-plastic strength. The release of chemicals substances from plastic products causes the accumulation of these harmful substances within the wildlife, and humans are a significant concern. Our invention would solve this problem to reduce or produce an alternative way to protect the environment from harmful substances. In addition of that, fruit waste has become one of the main sources of municipal solid wastes (MSW), which has become an increasingly tough environmental issue. However, inappropriate management of landfills will result in emissions of methane and carbon dioxide. Thus, utilization of the fruit wastes as sources of bioactive compounds may be of considerable economic benefits and has become increasingly attractive. Mango peels mixed into bioplastic could be an alternative way to protect the environment and reduce food waste. Mango peels have a high starch content, implying that they could be used to make bio-plastic. The bioplastic is produced from food waste material. Food waste material used from mango peel because of its high cellulose content and good availability. The bio-plastic film from mango peel was produced using simple home-based techniques. The films will be blended with glycerol as a plasticizer to give promising results. This is to give strength and flexibility to the plastics. After the materials are mixed together and boiled until it reaches its desired viscosity. The mixture will be dried in the oven. As a result, a thin sheet of dried pulp which can be rolled into a tube and sealed using a chopstick or any metal straw, creating the straw. We would like to collaborate with the food industry or any food packaging industry to improve or extend our project for characterization, such as mechanical testing to test the strength of the plastic. Other testing that could be done includes a thermal test for thermal resistance, biodegradable testing, and polyphenol content testing of mango peel. Due to a lack of equipment to produce high-quality eco-friendly straws or cutlery, collaboration with the food packaging industry for research and development is encouraged.

Komen