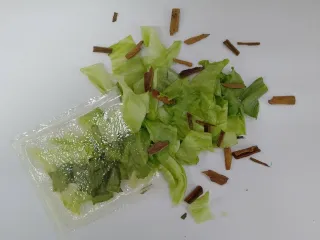

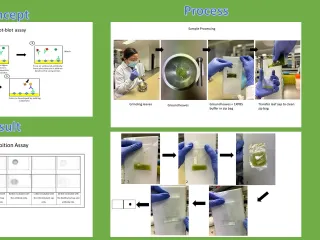

CinnaFresh is an innovative bio-renewable and sustainable active packaging that preserves fresh-cut produce quality through enzymatic browning and fungal inhibitions. It uses cellulose acetate, which biodegrades in 2 to 10 years, cinnamon bark extract and polyethylene glycol (PEG) 1450 as a food safe and bio-renewable active ingredient and plasticizer, respectively. CinnaFresh had been used to test six types of fresh-cut fruits and vegetables including apple, banana, celery, lettuce, mung bean sprout and potato at room temperature. It was effective to prevent the browning of low phenolic content samples (Below 54.39 ± 2.71 mg GAE/100 g FW) such as celery, lettuce and mung bean sprout for up to 4 days. This is because the bioactive compound of cinnamon bark extract, (E)-cinnamaldehyde is a competitive PPO inhibitor that its browning inhibition effect will be inhibited by high concentration of phenolic substrates presented in the fresh-cut produces. Meanwhile, it was effective in delaying mold growth for all the fresh-cut samples by up a week. An unexpected benefit is that it delays shrinkage when it was tested on fresh-cut lettuce. In comparison, unrefrigerated vegetables without packaging become unsalable within 2 days. Both enzymatic browning and fungal inhibitions on fresh-cut produces by CinnaFresh can be carried out without refrigeration. This could eventually reduce the refrigeration shelves to store the ready to buy fresh-cut produces. The product is transparent with a slight yellowish hue which is ideal for food packaging where consumers can inspect the fresh-cut produce in the packaging before purchasing. In addition, it can replace conventional plastic packaging that creating plastic wastes and pollution to the environment. With the validated result discussed earlier, CinnaFresh is placed at Technology Readiness Level 5 (TRL 5). The next steps involve finding investors or interested companies to provide capital to produce the packaging at demonstration scale and test it out on supermarket shelves. An initial investment of RM 122,000 for an extruder and sealing machine can produce 5000 units/day with capital recovery in as little as 175 days. CinnaFresh also fulfills sustainable development goals (SDG) no. 3, 9 and 12. It extending shelf life, reducing waste and improving food safety to promote good health and well-being (SDG 3), enhances existing food supply chains and reducing waste by using bio-substitution materials and active packaging (SDG 9) and reduces food waste and promotes sustainable consumption with bio-renewable active ingredients and materials (SDG 12). With fresh-cut produce values expected to double to 600 billion USD from 2022 to 2032, CinnaFresh can replace single-use plastic food packaging to extend shelf life without refrigeration.

Comment