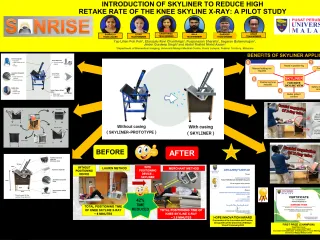

Introduction Of Skyliner To Reduce Retake Rates Of The Knee Skyline X-Ray: A Pilot Study

Description

General Radiography is an essential medical imaging examination that produces images of the internal structures and extremities to assist in the diagnosis. The knee X-Ray skyline view is among the common requests, constituting 13% of the medical imaging requests for extremities. However, the current skyline view, Laurin method, has a high repetition frequency (above 10%) in the Universiti Malaya Medical Centre (UMMC) due to blurred images caused by patient movement during exposure. Furthermore, repeat X-rays could increase the risk of radiation-induced cancer. Hence, corrective action is essential when the retake rate exceeds 10%. In addition, the existing mobility devices are not compatible or ergonomic for some patients, especially patients who are elderly or weak. The current practice of positioning method requires patients to hold the X-Ray detectors, which weigh 4kg. Should the detector be damaged due to a fall, the estimated cost of damage was approximately RM2.8 million (the risk of 14 times falls x RM200K). In Malaysia, only 23% have immobilisers available in their institutions for the skyline view (consisting of sandbags, spans, or chairs). Besides, about 70% of patients must hold the X-Ray cassette/detector during skyline view. The team members are proud to share that the Department of Biomedical Imaging, UMMC, is the first hospital in Malaysia to take the initiative to invent Skyliner. Therefore, the innovative Skyliner has helped reduce the retake rate of the knee skyline X-ray, reducing the radiation dose, time, and cost while producing better image quality.

Highlights

This innovative project was approved by the Head of the Department of Biomedical Imaging, Associate Professor Dr Khairul Azmi Abd Kadir. The high retake rate of the knee skyline X-Ray has a high impact on the stakeholders. Therefore, the team's action plan was based on 5W-1H (What-When-Where-Why-Who and How). The team analysed the possible root causes of the problem that contributed to the high retake rate of the knee skyline X-ray using the Ishikawa Fishbone diagram, which includes four primary categories: People, Method, Money, and Device. The team evaluated the first invention, which was called as Skyline Immobiliser Device. However, this device needed to be more suitable as the positioning device was fragile; hence the team rejected the application. The team continued to develop a more suitable device called Skyliner-Prototype and accepted the device after the verification and validation process by the team members, users and patients. This Skyliner is metal coated with anti-rust with an adjustable slotted angle bar. The Skyliner is more robust, sturdy, and easily cleaned. The Skyliner has a rubber base to protect the tiles, a roller for easy wheeling and a brake system. The Skyliner helps secure X-ray detectors and comfort the patient during positioning. Therefore, when using the Skyliner, the patients are not required to hold the X-Ray detector. The Skyliner also helps reduce the positioning time compared to the conventional method. The team conducted a phantom study to compare the dose to sensitive organs between the Laurin (without Skyliner) and the Merchant method (using Skyliner). The Merchant method received positive feedback among radiographers and medical officers. Based on the phantom study, the Merchant method reduced radiation dose by more than 90% when using the Skyliner. More than 90% of the radiographers agreed that the Skyliner eased the workflow as the device was ergonomic. Moreover, the medical officer rated more than 80% of the knee skyline images as "perfect" when using Skyliner. The project outcome showed zero retakes when using the Skyliner. The retake rate of the skyline view was reduced with 10% cost savings. The innovative Skyliner is much cheaper than the devices found in the market, which also helps to reduce the positioning time by up to 42%. This project positively impacted and added value to the stakeholders. As the team embarked on their innovative journey, their proud moment was recognition in January 2022 by winning the first prize at the Department Level for Quality Improvement (QI) Project: Innovation in Immobilisation (15 October 2022). In addition, the team received Hope Innovation Award in 2023 at the Innovative and Creative Group Convention, organised by Universiti Malaya (18 – 19 January 2023).

Contact Person/Inventor

| Name | Contact Phone | |

|---|---|---|

| LILIAN YAP POH POH | lilian@ummc.edu.my | 60123412759 |

Award

| Award Title | Award Achievement | Award Year Received |

|---|---|---|

| Malaysian Technology Expo | MTE 2023 | 2023 |

Video

Additional Document

| Attachment | Size |

|---|---|

| file-1711942058.pdf (4.99 MB) | 4.99 MB |

| file-1711942058.pdf (4.85 MB) | 4.85 MB |

| file-1711942058.pdf (830.48 KB) | 830.48 KB |

| file-1711942058.pdf (4.45 MB) | 4.45 MB |

| file-1711942058.pdf (98.14 KB) | 98.14 KB |

Comment